Optical lenses, filters, and components have applications in many industrial processes. Different types of optical equipment make it possible to automate manufacturing processes, visualize details of distant terrain, and analyze the elements present in a sample, for example.

OSE Optics specializes in precision lens engineering, design, and assembly for industries including biomedical, semiconductor, military, and manufacturing. We also provide efficient, just-in-time manufacturing, high-precision optical alignment services, and build-to-print expertise.

Overview of Optical Lenses in Industrial Operations

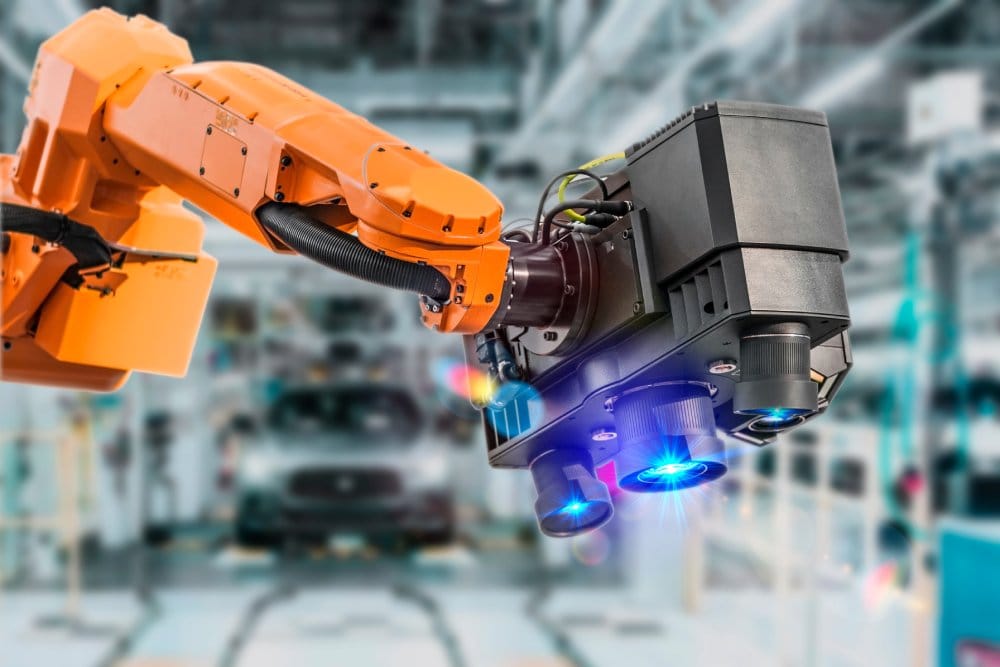

Industrial lenses are specialized for use in manufacturing and other industrial settings. The lenses focus or direct light and gather data for computerized image processing, laser processing operations, spectral analysis, and comparison against sample data.

Many types of lenses and optical components are available for a wide range of application requirements. These include variable and fixed magnification lenses, telecentric lenses, spherical and aspherical lenses, prisms, mirrors, and filters.

Optical Lenses in Industrial Operations: Capabilities

The in-house engineering team at OSE Optics provides optical system assembly, device and instrument assembly and manufacturing, and optical metrology for testing and verification.

Our optical technology expertise includes:

- Machine vision systems

- Spectroscopy lenses

- Laser processing specifications for various key laser system components

- Hyperspectral imaging

Capabilities and services we provide include:

- On demand, high-precision optical system alignment

- Specialized optical testing to address any optomechanical and optical needs

- Custom build-to-print manufacturing and assembly

- Timely and efficient delivery of high-quality, tested optical systems

- Dedicated workspace for custom projects

- Kanban-style inventory management for just-in-time production

Optical Lenses in Industrial Operations: Applications

Industrial lenses are essential across various

industries, utilizing the unique properties of light for

precise analysis and manipulation. These lenses

support critical applications in manufacturing,

quality assurance, and environmental assessment.

Here’s how they are employed in several key

industrial applications:

- Laser processing: In manufacturing, lasers can be used to change the shape or look of materials such as metals, polymers, and ceramics. Lenses focus the laser light precisely for a range of operations including drilling, cutting, etching, or marking, without retooling between operations.

- Spectroscopy: Spectroscopy is used to study the elemental composition of material samples and the wavelengths they emit. Collimating lenses guide light in parallel lines as it enters the sample.

- Multispectral imaging: Specialized filters and lenses are used to separate and measure light in different ranges of wavelengths (i.e., spectral bands) for mapping and creating detailed images of different types of terrain. Plants, soil and geological features, buildings and structures, underwater features and structures, and fire can be detected by measuring different spectral bands.

- Machine vision: Machine vision systems are used in manufacturing for part verification, quality inspection, positioning automated tooling to create part features like holes and bend angles, and aligning dispensers for paint, glue, or labels. Machine vision can also be used in coordinate measurement machine (CMM) systems to check dimensions and tolerances on manufactured parts. Lenses ensure visual data is captured for processing and analysis. In some applications, data can be transmitted to motion control or robotic equipment to complete operations automatically.

- Optical sorting: Optical filters and lenses measure different light wavelengths to map and measure the dimensions and features of a part, comparing them to acceptable tolerances. Used in conjunction with automated conveyors, pushers, and chute systems at the end of a production line, defective or out-of-tolerance parts can be discarded quickly.

Optical Lenses from Optical Sourcing Experts

Off-the-shelf optical products are convenient, but rarely meet your unique requirements. Unfortunately, designing and building a custom solution yourself is complex and time-consuming.

At OSE Optics, we are committed to assisting clients with optical assembly, testing, and specialized technical assembly. We can also help you assemble lenses, filters, prisms, and other optical components for customized uses.

Trust our team to provide attention to detail, efficient production, and absolutely no shortcuts.

Contact us to connect with one of our experts today.